LEWA pump head technology

LEWA offers the most advanced pump technology in the world. Our pump heads in particular are characterized by their high reliability, efficiency and power. Get to know our technology for different applications with diaphragm pump heads from the M500, M900, M800, M200/M400 series as well as our K110/K210 plunger pump heads.

LEWA intellidrive

Using the highly-dynamic servomotor, you can model the stroke of the pump to the requirements of your system and your process. The stroke adjustment normally required for metering pumps can then be omitted. Infinitely variable stroke times permit the metering pump to handle new application areas with special fluid kinematics.

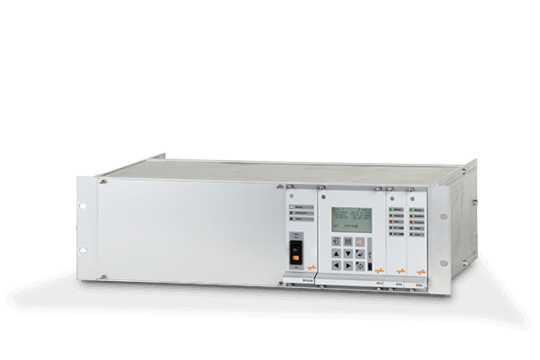

Smart control technology

Based on the systematically collected experience with flow controlled metering systems, LEWA designed a controller that meets all the important requirements on the "brain" of metering systems. The control unit continually compares the flow rates (using a flowmeter) with the target values (defined by the user or via PCS).

Diaphragm monitoring system

LEWA diaphragm pumps are frequently used for metering or conveying very hazardous liquids Leaks caused by diaphragm damage are not permissible. For this reason LEWA already developed and patented a reliable and simple sandwich diaphragm technology with monitoring in 1968.

Pump synchronisation

LEWA pump synchronisation modulates multiple pumps in one application to reduce pulsation in the piping system. Other advantages of pump synchronization are conservation of materials by running the pumps in a lower frequency area and more flexibility for stand by concepts.

LEWA Odor Control Unit

In an odorizing process, an odorant is added to an odorless, potentially dangerous gas to early detect gas leakage and to prevent accidents. To ensure that the correct amount of the odorant is metered, LEWA has developed a modular control unit for odorization.