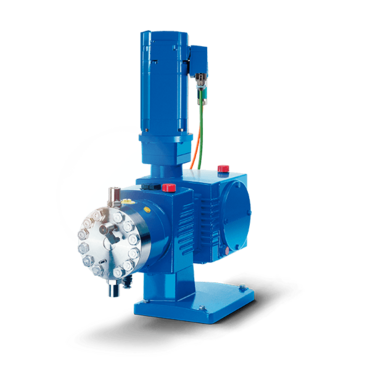

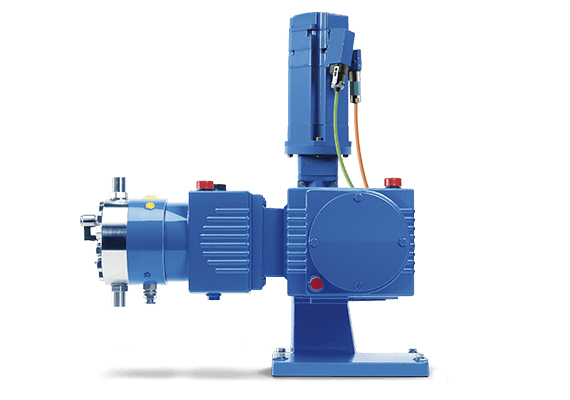

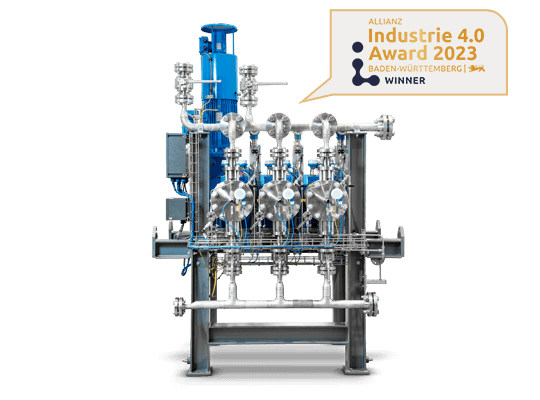

LEWA intellidrive®: Specialized Kinematic Diaphragm Metering Pump for Chromatography

Metering pumps for special fluid kinematics.

The LEWA intellidrive® metering pump is the pinnacle of innovation for special kinematic applications, such as high-precision chromatography in the pharmaceutical sector. This advanced technology, featuring a dynamic servomotor, provides infinitely variable stroke times, enabling the customization of pumping characteristics to meet the specific kinematic needs of your system and process.

Its intelligent motion control excels in metering highly viscous fluids and executing precise, small-volume dosing across extensive control ranges. When paired with a secondary pump, the intellidrive technology ensures near-pulsation-free volume flows through meticulous synchronization.

Available in both LEWA ecoflow and ecodos models, the intellidrive® system adapts to special metering requirements, offering unparalleled precision and control for chromatography processes and other applications where exact fluid kinetics are crucial."

Key Advantages of LEWA intellidrive®: Special Kinematics Metering Pump for Chromatography

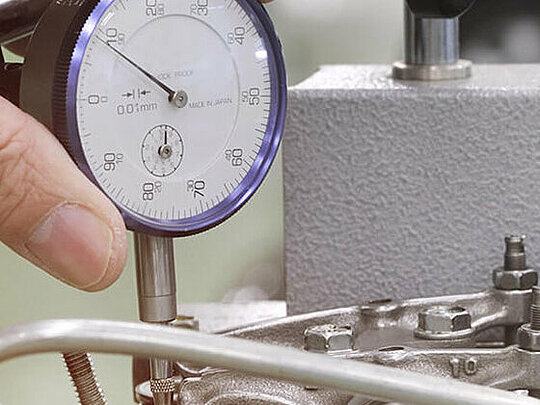

LEWA intellidrive pumps stand out as mechatronic diaphragm metering pumps equipped with special intelligent drive technology, tailored for precise kinematics in chromatography applications. The innovative servomotor drive offers numerous advantages over conventional drive technologies, enhancing metering accuracy and reliability.

Fluids with high viscosities

Through the decelerated suction stroke, the LEWA intellidrive is very well suited for fluids with high viscosities up to 100.000 mPa∙s e.g. honey. This characteristic makes LEWA intellidrive unique in comparison to other pumps.

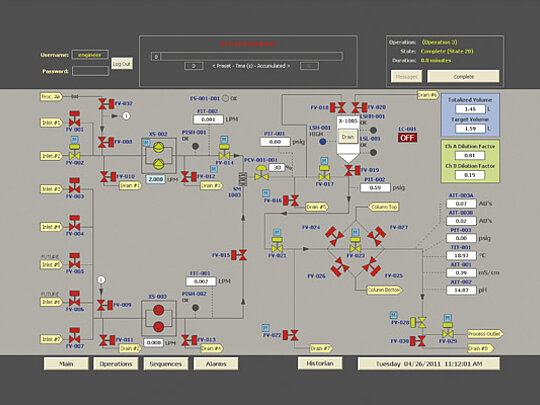

Easy integration into higher-level process control systems

Interfaces such as Ethernet and Profibus ensure problem-free system integration. Pumps can be integrated as field equipment in the higher-level process control technology. Prefabricated plugs on the pump motor connect the supply and signal lines with the control unit. Analog inputs and outputs, for example for valve control, can be expanded.

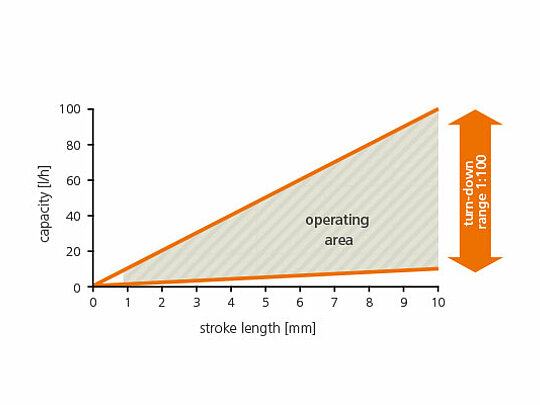

Large adjustment range

Precision is our strength: The drive of the LEWA intellidrive metering pump can be configured in an extremely large control range of at least 1:150. This allows us to fulfill the most stringent requirements for sensitive metering tasks, for example in the pharmaceutical industry.

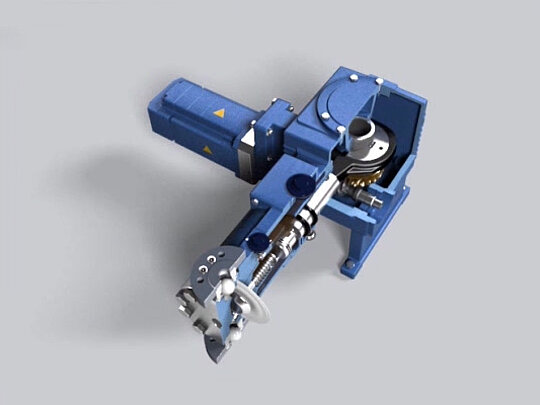

Individual suction and discharge stroke characteristics

The LEWA intellidrive technology can be used to model, program and save individual suction and discharge stroke characteristics. Using various suction and discharge stroke frequencies, high-viscosity fluids are drawn in slowly and with low pressure loss via the smaller valve nominal width – and then quickly fed to the process in the discharge stroke.

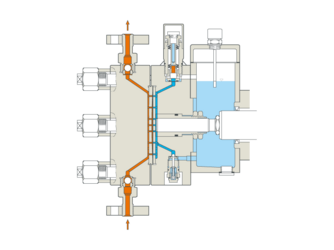

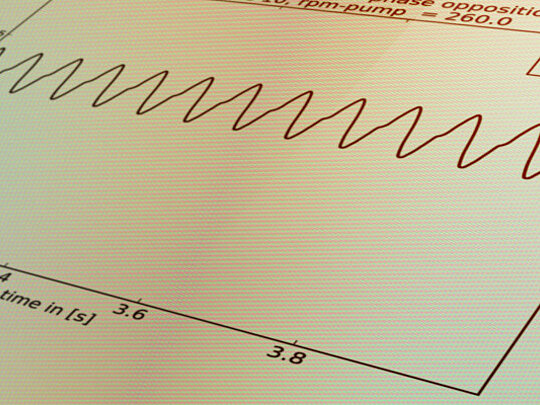

Synchronization of pumps for pulsation reduction

By using two synchronized intellidrive pumps, a virtually pulsation-free volume flow can be generated. Therefore, the piping system, in some cases, can make do without pulsation dampers. These are often hard to clean, particularly in hygienic applications.

Precise filling tasks and fluid chromatography

Infinitely variable stroke times permit fluids with special kinematics to be moved successfully. This makes it terrifically well suited as a metering pump in filling tasks or in highly precise chromatography systems in the pharmaceutical area.

Suitable for the smallest flow rates

The LEWA intellidrive implements extremely small flow rates up to 1 ml/h with precision. No other industrial pump reaches the degree of precision often required in pharmaceutical and biotechnological processes.

API 675 standard

The intellidrive series fulfills the internationally valid quality standard of the American Petroleum Institute API 675. In this standard, all requirements for a displacement pump in industrial settings are defined with respect to design, construction and performance. We would be happy to present you with further certifications, if desired.

LEWA Smart Monitoring

With digital pumps for more efficiency, system availability and profitability of the entire production.

LEWA Smart Monitoring is a monitoring system consisting of sensors, a programmable logic controller (PLC), an industrial PC (IPC) and data analysis for new and existing pumps. The system determines characteristic values and key performance indicators. There is no intervention in process control or direct contact between the sensor system and the conveyed fluid.

With key performance indicator-based condition monitoring, you detect and monitor operating statuses proactively. You can also optimize the overall output and robustness of your pump and pipe systems. This will increase the efficiency of your entire production plant. You can access the data conveniently via your corporate network. Or you use the LEWA cloud with extended analysis and service offers.

Learn more about LEWA Smart Monitoring

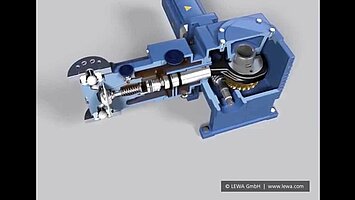

Exploring Special Kinematics: Videos on LEWA intellidrive® Metering Pumps

LEWA intellidrive with servomotor

Full animation of LEWA intellidrive technology. Mechatronic metering pump with servomotor to generate individual stroke characteristics.

Options

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Diverse connection geometries

Our pumps are equipped with all common connection geometries such as DIN standard, BASF's high-pressure standard, American ANSI, JIS, or your individual requirements. Customized configurations are possible.

Heating and cooling jacket

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Special design materials

If the process demands it, wetted parts such as pumps heads and valves will be made of special materials such as stainless steel 316/316L (1.4401/1.4404), Hastelloy or Duplex steel and PVC.

Diagnostic connection

Our pumps and systems have connections that facilitate the diagnosis of their performance. This is done by a service technician on site or via remote monitoring.

Integrated pressure relief valve

An integrated pressure relief valve prevents potential overload situations. The valve is individually adjustable and can be adapted to different operating situations.

Sanitary & hygienic design

LEWA pumps and systems in sanitary & hygienic design are available for applications that require extremely high purity, such as food production and the pharmaceutical industry.

CIP and SIP capability

Many LEWA pumps, systems and units can be cleaned (Cleaning in Place) and sterilized (Sterilization in Place). To carry this out, it is not necessary to disassemble the equipment.

Complete documentation

In the process of documentation, we consider your requirements and provide inspection records, print samples, diagrams of output characteristics and registration papers on request.

Product Range: Kinematics Metering Pumps by LEWA Intellidrive®

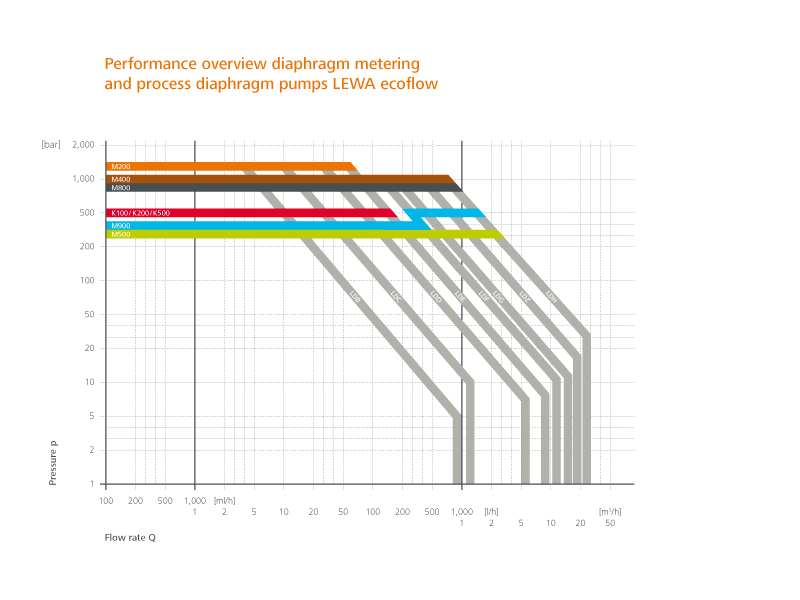

The LEWA intellidrive diaphragm metering pump, with its array of specialized pump heads, spans a broad performance spectrum, catering to a wide range of kinematic requirements. We deliver a high-performance, energy-efficient pump solution tailored to your specific metering application needs.

Installation dimensions

Save space and weight through multiplex arrangement of pumps or arrangement in the compact boxer design.

| Type | L [mm] | W [mm] | H [mm] |

|---|---|---|---|

| LDB | 400 | 400 | 260 |

| LDC | 450 | 500 | 320 |

| LDD | 700 | 750 | 610 |

| LDE | 800 | 900 | 690 |

Performance data

| Pump type/flow rate [l/h] | Permitted pressure for stainless steel [bar] | Permitted pressure for plastic [bar] | |||

|---|---|---|---|---|---|

| VA | PVC | PVDF | |||

| 2 | 20 | 12 | 80 | 60 | 80 |

| 4 | 20 | 12 | 80 | 60 | 80 |

| 6 | 20 | 12 | 80 | 60 | 80 |

| 12 | 20 | 12 | 80 | 60 | 80 |

| 25 | 10 | 10 | 80 | 60 | 80 |

| 50 | 10 | 10 | 80 | 60 | 80 |

| 90 | 10 | 10 | 80 | 60 | 80 |

| 180 | 10 | 10 | 80 | 60 | 80 |

| 350 | 7.5 | 7.5 | 80 | 60 | 80 |

| 550 | 7.5 | 7.5 | 80 | 60 | 80 |

| 750 | 5 | 5 | 80 | 60 | 80 |

| 1100 | 5 | 5 | 80 | 60 | 80 |

| 1500 | 5 | 5 | 80 | 60 | 80 |

Pump Head Variants: Kinematic Metering Pumps by LEWA

We provide various pump heads for different applications. Here, the spectrum ranges from all-purpose variants to special designs for high temperatures, pressures or aggressive fluids.

Pump head ecodos (ohne Abbildung)

Mechanically actuated diaphragm pump head with monitored four-layer PTFE sandwich diaphragm; very robust pump head technology for pressures up to 20 bar.

| Type | ecodos |

| Pressure | 20 bar |

| Flow rate | 1,5 m³/h |

| Temperature | +80 °C |

| Viscosity | 500 mPa∙s |

| Operational capability | Can be installed on all intellidrive ecodos diaphragm metering pumps. |

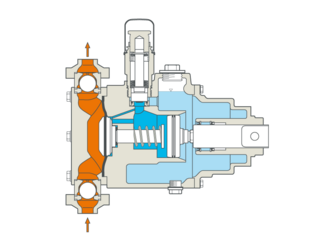

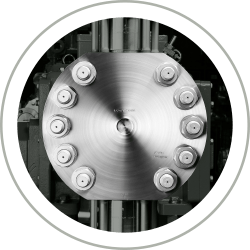

Pump head M900

State of the art universal diaphragm pump head with PTFE sandwich diaphragm for maximum operational safety. Robust and reliable with unmatched standard of protection against difficult start up, faulty operation and upset conditions. The patented DPS technology also enables a suction lift capability that is globally unique in the field of hydraulically actuated diaphragm pumps.

| Type | M900 |

| Pressure | 500 bar |

| Flow rate | 6 m³/h |

| Temperature | -20/+150 °C |

| Viscosity | 100.000 mPa∙s |

| Operational capability | Can be installed on all ecoflow diaphragm metering pumps |

Pump head M200/M400

Proven pump head with metal diaphragm for extreme pressures and high temperatures. Also suitable when a high degree of permeation resistance is required. The diaphragm is working between two contour plates, limiting the deflection of the diaphragm and providing an extreme level of operational reliability. The diaphragm monitoring system offers a plus for safety by immediately displaying the damage of a diaphragm layer.

| Type | M200/M400 |

| Pressure | 1.200 bar |

| Flow rate | 1,1 m³/h (M200) 0,8 m³/h (M400) |

| Temperature | -40/+200 °C |

| Viscosity | 500 mPa∙s |

| Operational capability | M200 can be installed on all ecoflow diaphragm metering pumps ≤ LDE, M400 can be installed on all ecoflow process diaphragm pumps ≥ LDF. |

Industries

Chemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Downstream processing

LEWA systems and gradient mixers are used in downstream processing of chemicals and biotechnology. We look forward to receiving your inquiry!

More DetailsPharmaceutical spray drying

LEWA provides accurate and efficient diaphragm metering pumps for pharmaceutical spray drying. Consult us!

More DetailsContinuous metering of extremely small quantities with LEWA intellidrive

Minimum flow rates down to 1 ml/h: With LEWA intellidrive technology, we already have created solutions for many applications with very small flow rates.

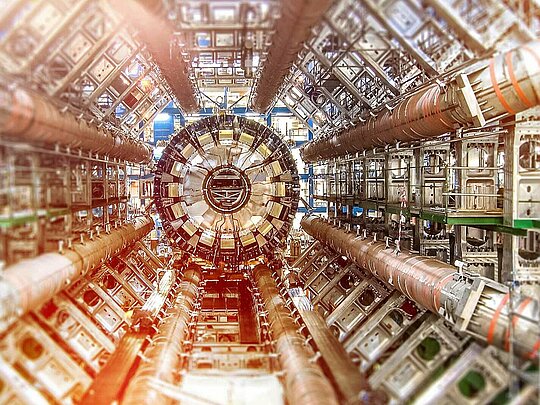

More DetailsOil-free CO2 cooling with LEWA pumps

LEWA diaphragm metering pumps provide a constant oil-free CO2 cooling of silicon sensors in particle physics research center CERN.

More DetailsDilution of emulsifiers

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant emulsifier dilution.

More DetailsExtracting omega-3 fatty acids using supercritical CO2

LEWA offers optimum pump solutions for these processes, which perform their tasks safe, permanently reliable and efficiently

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsSolutions for flavor and color metering in the confectionery industry

LEWA creates custom-made, complete solutions that are ready to implement in your applications.

More DetailsDownloads

LEWA ecoflow maßgeschneiderte Dosierpumpen (DE)

LEWA ecoflow ist ein umfangreiches Baukastensystem für Membran- und Kolbenpumpen. Es kombiniert sieben Triebwerksgrößen mit sechs unterschiedlichen Pumpenköpfen.

3 MB

| pdf |

18.02.2022

LEWA ecoflow bombas dosadoras customizadas (PT)

A ecoflow LEWA é um extensivo sistema modular para bombas dosadoras de diafragma e de pistão.

Ela combina sete tamanhos de unidade com seis diferentes cabeças de bomba.

3 MB

| pdf |

18.02.2022

LEWA ecoflow custom-made metering pumps (EN)

LEWA ecoflow is an extensive modular system for diaphragm and packed plunger metering pumps.

It combines seven drive sizes with six different pump heads.

3 MB

| pdf |

18.02.2022