LEWA FC micro-metering pumps

Laboratory pumps for extremely small flow rates.

In laboratory settings, test centers, and other precise testing environments, metering small quantities of liquid media is a common requirement. These applications demand operational reliability, versatility, and the ability to produce reproducible and highly precise metered flows, while ensuring the media remains uncontaminated.

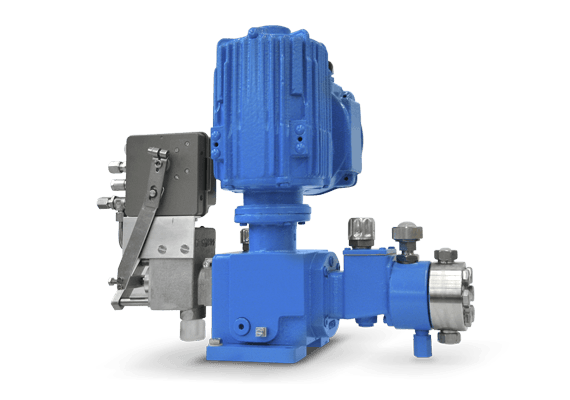

The LEWA FC micro-metering pump excels as a laboratory pump, meeting these stringent criteria with remarkable efficiency and metering accuracy of ±1%. Its design allows for the combination of multiple pump heads and drives, creating versatile multiplex pumps capable of achieving higher flow rates or managing various fluids sequentially.

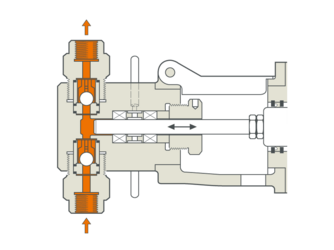

To accommodate diverse applications and meet specific customer needs, the LEWA FC is offered in two configurations: as a diaphragm pump for utmost purity and a packed plunger metering pump for robust precision. This adaptability ensures the LEWA FC micro-metering pump's suitability across a broad range of laboratory applications.

Top Advantages of LEWA Micro-Metering Laboratory Pumps: Precision & Reliability

LEWA FC laboratory pumps, ideal for micro-metering applications, come in two designs: hydraulically actuated diaphragm metering pumps for precise, contamination-free operations, and mechanically actuated packed plunger metering pumps for robust precision.

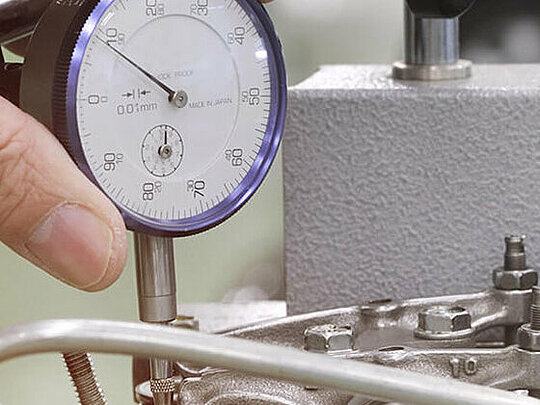

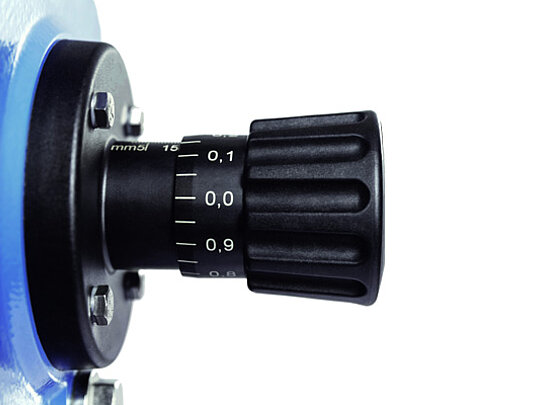

Highest metering accuracy

The flow rate can be configured with absolute precision. The micro-metering pump works with an accuracy of ± 1%. This allows you to meter fluids in a process in precisely defined quantities. LEWA pumps feature this enormous precision.

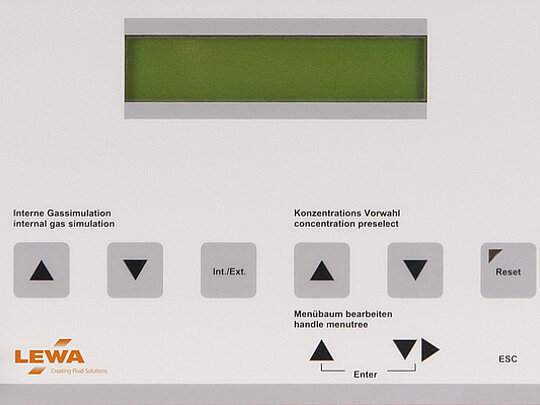

Control and monitoring electronics

We analyze the requirements that develop from your use and supply the suitable micro-metering pump including specifically adjusted control and monitoring electronics. This allows you to achieve maximum efficiency when operating your systems.

Accurately operating drive unit

Absolute precision is our standard: LEWA micro-metering pumps have accurately operating drive units with an electric drive and a plunger spring return that is friction-locking and absolutely free of play. Thus, they are particularly well suited for laboratory applications in which precise metering is required.

Leak-proof and odor tight

LEWA micro-metering pumps are not only leak-proof, but also absolutely odor-tight.

Oil lubrication

All moving parts are continuously lubricated with oil. The pump is protected from weather and splash water.

Integrated pressure relief valve

A pressure relief valve in the hydraulic part of the diaphragm pump prevents potential overload situations in operation. This valve is individually adjustable and can therefore be adapted to different operating situations.

Advantageous kinematics

The cam and spring drive has advantageous drive kinematics for the smallest metered flows.

Superior metal diaphragm technology

The metering pumps are equipped with sophisticated metal diaphragm technology, which enables discharge pressures up to 500 bar. At the same time, they still meter very precisely at an accuracy of ± 1%.

Wide adjustment range

The LEWA micro-metering pumps can be regulated in a wide adjustment range with consistently high efficiency and rigid compression curve.

Low-noise

The micro-metering pump is absolutely noiseless in operation, making it ideal for laboratory environments.

Dry-run safe and maintenance-friendly

The pumps are dry-run safe and maintenance friendly. No sliding seals or packages are inserted. This guarantees the highest process safety.

Ideal for supercritical and expensive fluids

FC micro-metering pumps are suitable for handling supercritical or expensive fluids due to precise and safe metering.

Features of LEWA Micro-Metering Laboratory Pumps: Customized Precision

Multiplex capability

Single drive units with vertically installed motor are space-saving. Alternatively, multiple drive units with identical or different output can be combined for pulsation reduction or recipe metering.

Minimization of pulsation

Multiple pumps designed for the minimization of pulsation can avoid the use of pulsation dampers. Ideal for perishable or slightly contaminated fluids (CIP/SIP capable).

Explosion-proof design

We supply pumps, equipment and systems on request in explosion-proof design for operation up to EX zone 1 . Thus, we guarantee maximum security.

Special micro filters

On demand, we equip your pump with special micro filters for dealing with high-purity fluids. This is especially recommended for applications in the pharmaceutical and food industry.

Special design materials

If the process demands it, wetted parts such as pumps heads and valves will be made of special materials such as stainless steel 316/316L (1.4401/1.4404), Hastelloy or Duplex steel and PVC.

Heating and cooling jackets

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Electrical stroke adjustment

Adjust the stroke length of your pump exactly to the specific metering task: LEWA pumps can be set fully automated by an electric stroke adjustment with integrated regulator.

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Complete control/regulation program

Our pumps and systems come with a complete control/regulation program. Moreover, the use of programmable logic controllers (PLC) is possible.

Technical Data

The FC micro-metering pump is particularly well-suited for low flow rates at high pressure. Here, it is available in standard configuration.

Performance data

| Type | Stroke length [mm] | Plunger rod force [N] |

|---|---|---|

| FC | 10 | 800 |

Installation dimensions

| Type | L [mm] | B [mm] | ΔB [mm] | H [mm] |

|---|---|---|---|---|

| FC | 375 | 164 | 120 | 400 |

Pump head variants

The LEWA FC micro-metering pump can be equipped with a plunger or diaphragm pump head.

Pump Head K110 (Piston)

Standard pump head with single gland for pressures up to 160 bar.

| Type | K110/K111 |

| Pressure | 160 bar |

| Flowrate | 65 l/h |

| Temperature | -70/+400 °C |

| Viscosity | 1.000 mPa∙s |

Pump head M213 (Diaphragm)

Pump head for pressures up to 400 bar.

| Type | M213 |

| Pressure | 400 bar |

| Flow rate | 1,5 l/h |

| Temperature | -30/+120 °C |

| Viscosity | 50 mPa∙s |

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Downstream processing

LEWA systems and gradient mixers are used in downstream processing of chemicals and biotechnology. We look forward to receiving your inquiry!

More DetailsExtraction with supercritical fluids

Processes with supercritical fluids in pharmaceutical, food and beverage industries. Ask our experts for more information!

More DetailsPharmaceuticals production

Metering pumps and metering systems must meet the following demands of pharmaceutical production.

More DetailsMetering of silane

LEWA systems meter any silane type reliably, precisely as well as in constant consistency and purity, regardless of chemical or physical attributes or process requirements.

More DetailsContinuous metering of extremely small quantities with LEWA intellidrive

Minimum flow rates down to 1 ml/h: With LEWA intellidrive technology, we already have created solutions for many applications with very small flow rates.

More DetailsOil-free CO2 cooling with LEWA pumps

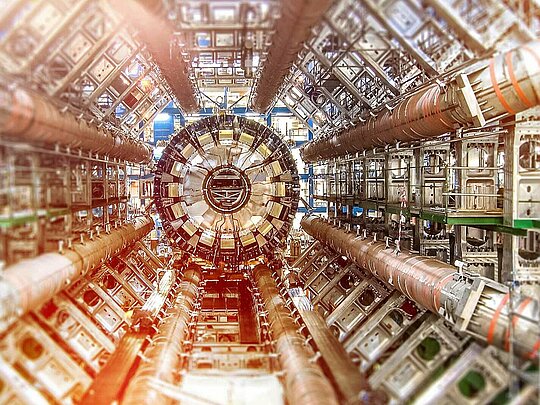

LEWA diaphragm metering pumps provide a constant oil-free CO2 cooling of silicon sensors in particle physics research center CERN.

More DetailsDilution of emulsifiers

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant emulsifier dilution.

More DetailsExtracting omega-3 fatty acids using supercritical CO2

LEWA offers optimum pump solutions for these processes, which perform their tasks safe, permanently reliable and efficiently

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsEsterification

With LEWA process diaphragm pumps, as well as the NIKKISO Non-Seal canned motor pumps we offer the optimum solution for esterification.

More DetailsDownloads

LEWA Micrometering pumps (USA)

Micro-metering pumps with diaphragm technology for metering fluids in laboratories and test centers.

1 MB

| pdf |

18.02.2022

LEWA Mikrodosierpumpen (DE)

Mikrodosierpumpen mit Membrantechnologie für die Dosierung von Flüssigkeiten in Labor und Technikum.

2 MB

| pdf |

18.02.2022

LEWA Micrometering pumps (EN)

Micrometering pumps with diaphragm technology for metering fluids in laboratories and test centers.

2 MB

| pdf |

18.02.2022