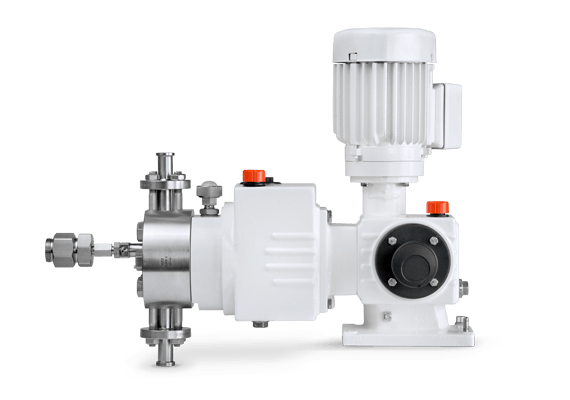

Discover LEWA ecoflow®: Your Trusted Solution for Sanitary and Hygienic Metering Pumps

The first choice among pharmaceutical and food production pumps.

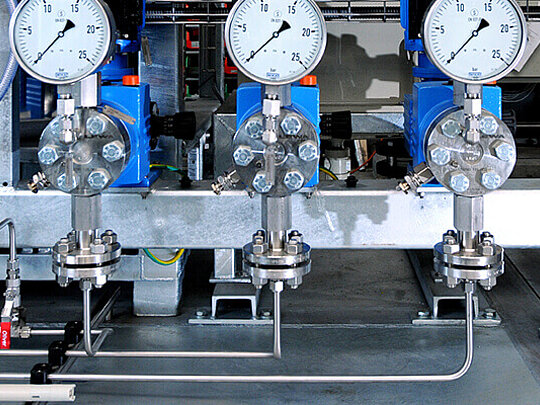

In the production of food and pharmaceuticals, strict process technology requirements are paramount. That's why we offer the trusted LEWA ecoflow diaphragm metering pump in sanitary/hygienic design, ensuring compliance with rigorous standards.

Our sanitary/hygienic pumps combine ecoflow's precision and reliability with tailored adaptations for hygienic environments, such as minimal dead space and polished surfaces.

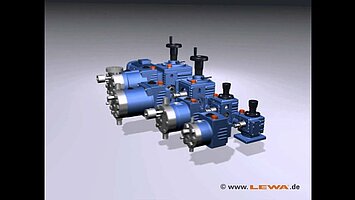

With our modular system, ecoflow pumps in sanitary/hygienic design can be configured with various pump heads and drives to suit virtually any application in food and pharmaceutical industries.

We uphold technological and quality standards by equipping each ecoflow pump with the patented DPS diaphragm protection system, manufactured in Germany.

Discover the Benefits of LEWA ecoflow® Sanitary/Hygienic Metering Pump

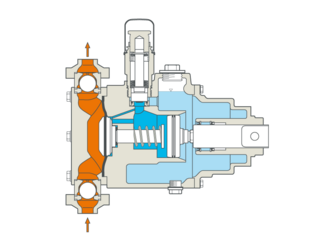

The LEWA ecoflow sanitary/hygienic pump is a hydraulically actuated diaphragm metering pump designed for use in hygienic applications within the food and pharmaceutical industries, offering multiple advantages compared to similar pumps.

Sanitary/hygienic-compliant design

Special requirements apply for use in the production of food and pharmaceuticals: LEWA ecoflow sanitary/hygienic fulfills these with polished surfaces and minimal dead space. All industry-standard certifications are available.

FDA-compliant parts in direct contact with pumped fluid

All LEWA ecoflow diaphragm metering pump parts in sanitary/hygienic design in direct contact with pumped fluid are FDA-compliant. They are also animal fat free and inspected and documented in accordance with USP Class VI. Thus, we guarantee absolutely hygienic processes and safe use.

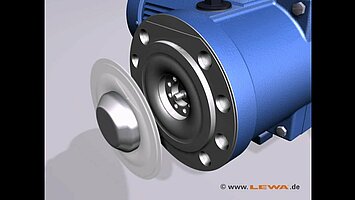

Absolutely safe startup

Starting up the ecoflow pump is safe and easy: When not operating, a spring always pulls the diaphragm into a neutral position. This ensures that the diaphragm is never damaged due to incorrect positioning when starting up.

Unique suction capability

The LEWA ecoflow diaphragm metering pump in sanitary/hygienic design differs from other pumps due to its unique suction capacity. With an absolute suction pressure of up to 0.1 bar, it not only provides a wide array of safe installation options, but the operating costs for the entire system can also be lower than with comparable pumps.

Low maintenance costs and a long service life

The ecoflow series features a long service life for all components and particularly low maintenance and operating costs. If the regular maintenance intervals are maintained, our diaphragm pumps can operate for 40 years or more in your production process.

API 675‐Standard

The ecoflow series fulfills the internationally valid quality standard of the American Petroleum Institute API 675. It includes all definitions for a diaphragm metering pump in industrial use in terms of its design, construction, performance and acceptance test.

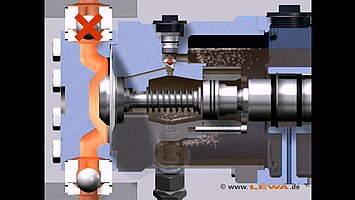

Safety and reliability in extreme operating states

For us, safety and reliability comes first: The pump is not subjected to damage, even after operating errors occur or in extreme operating states. We offer maximum protection for user and machine through built-in safety mechanisms - not only when excess primary pressure is present, but also when the pressure or suction line is closed.

Surfaces polished mechanically

For complying with the strict sanitary/hygienic standards, all surfaces of the pumps are mechanically polished (1.4571: RA < 0.8 µm) or electro-polished (1.4435: RA < 0.5 µm).

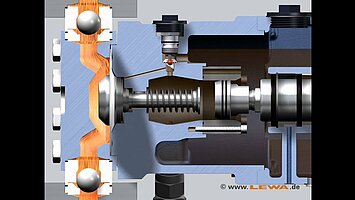

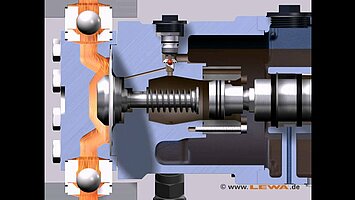

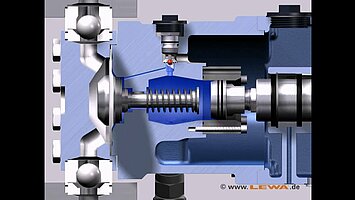

Patented sandwich diaphragm

Our patented LEWA sandwich diaphragm is not only extremely durable, but also well-protected. The LEWA DPS diaphragm protection system and a diaphragm monitoring system allow us to ensure that the diaphragm does not tear during operation and that the pump fluid is not contaminated.

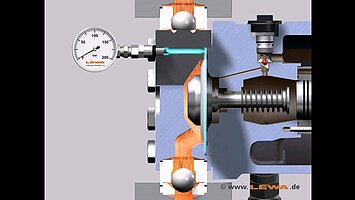

Integrated pressure relief valve

A pressure relief valve in the hydraulic part of the diaphragm pump prevents potential overload situations in operation. This valve is individually adjustable and can therefore be adapted to different operating situations.

Simple cleaning and sterilization (CIP & SIP)

LEWA ecoflow pumps can be cleaned (cleaning in place) and sterilized (sterilization in place) easily without requiring the system to be disassembled.

Complete traceability of all material products

All material products are completely documented and traceable in accordance with EN 10204 3.1b.

High energy efficiency

LEWA diaphragm pumps achieve the highest efficiency of all pump technologies. Our ecoflow series also combines high efficiency with low energy consumption.

Mixing various fluids

Run multiplex pumps, if desired, with different speeds. Thus, fluids with very different viscosities can be conveyed and mixed cost-effectively using one pump.

Worldwide standards

When designing pumps, we adhere to globally valid standards such as VDMA 24284, 24286‐10 and FDA guidelines.

Hermetically sealed

Diaphragm pumps work without dynamic seals in the process fluid area. This forms a hermetically sealed working area. No emissions escape to the outside, and contamination of the fluid is impossible.

Explore Informative Videos Featuring LEWA ecoflow®'s Sanitary/Hygienic Metering Pumps

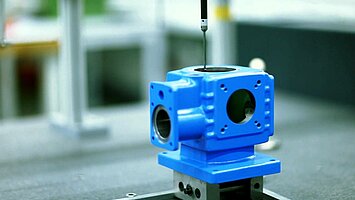

LEWA Creating ecoflow

Typical production of a LEWA ecoflow diaphragm metering pump in the production plant in Leonberg, Germany. Covers the full cycle from parts production to quality control, assembly, testing and shipment.

LEWA Creating ecoflow

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

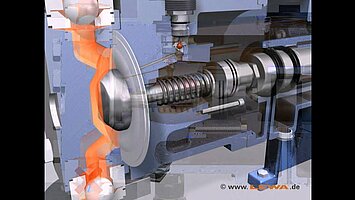

LEWA ecoflow – complete animation

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – snifting valve

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – pressure relief valve

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow – pressure in pump head M910

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow - multiplex drive element

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow - mounting of diaphragm

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow - diaphragm monitoring

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA ecoflow - M910 upset suction condition

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

Key Features of Sanitary/Hygienic Metering Pumps

Multiplex capability

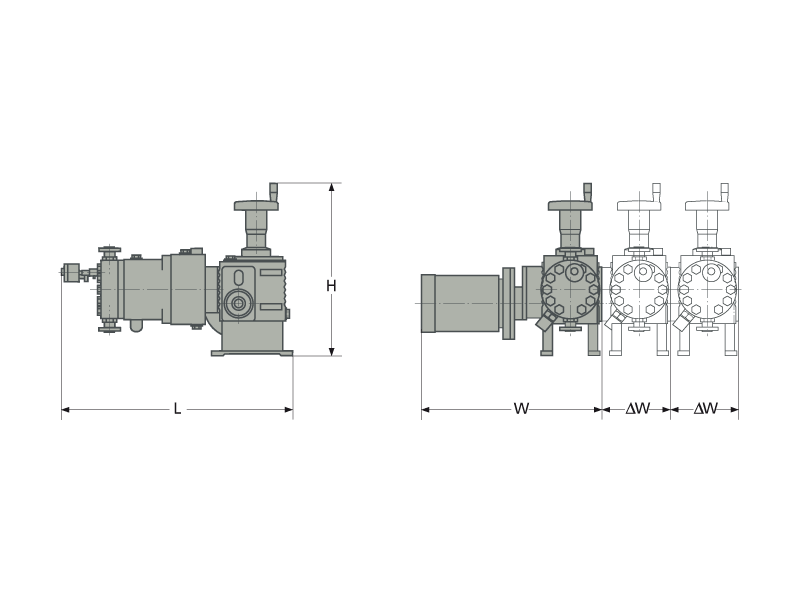

Single drive units with vertically installed motor are space-saving. Alternatively, multiple drive units with identical or different output can be combined for pulsation reduction or recipe metering.

Minimization of pulsation

Multiple pumps designed for the minimization of pulsation can avoid the use of pulsation dampers. Ideal for perishable or slightly contaminated fluids (CIP/SIP capable).

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Diverse connection geometries

Our pumps are equipped with all common connection geometries such as DIN standard, BASF's high-pressure standard, American ANSI, JIS, or your individual requirements. Customized configurations are possible.

Pressure and flow monitoring

With the LEWA smart control monitoring system, we ensure permanent monitoring and precise control of flow and pressure in your pump.

Special drive units for clean rooms

For applications in pharmaceutical, cosmetic, and food industry, we supply water cooled special drive units for clean rooms to prevent contamination and dust formation.

Explosion-proof design

We supply pumps, equipment and systems on request in explosion-proof design for operation up to EX zone 1 . Thus, we guarantee maximum security.

Heating and cooling jacket

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Intellidrive technology

Using the highly-dynamic servomotor, you can adjust the stroke of the pump to the requirements of your system and your process.

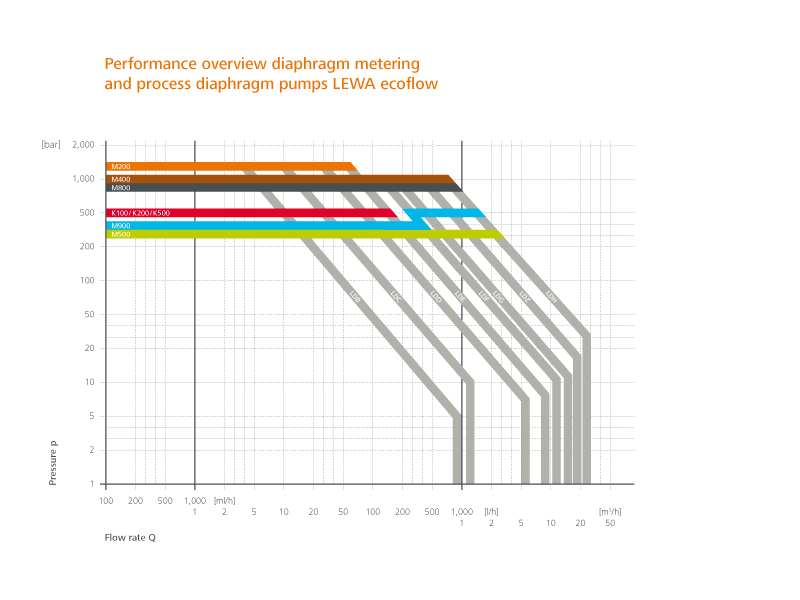

Explore LEWA ecoflow®'s Comprehensive Product Range

With various pump heads and gear units, LEWA ecoflow diaphragm metering pumps in sanitary/hygienic design offer a broad performance spectrum. This ensures the delivery of high-performance, energy-saving pumps tailored to your specific application needs.

Pump Head Variants: Enhance Performance and Versatility in Sanitary/Hygienic Metering Pumps

We offer a variety of pump heads tailored for different applications, ranging from versatile all-purpose variants to specialized designs suitable for high temperatures, pressures, or aggressive fluids in Sanitary/Hygienic Metering Pumps.

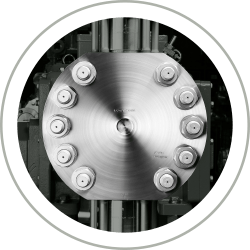

Pump head M900

State of the art universal diaphragm pump head with PTFE sandwich diaphragm for maximum operational safety. Robust and reliable with unmatched standard of protection against difficult start up, faulty operation and upset conditions. The patented DPS technology also enables a suction lift capability that is globally unique in the field of hydraulically actuated diaphragm pumps.

| Type | M900 |

| Pressure | 500 bar |

| Flow rate | 6 m³/h |

| Temperature | -20/+150 °C |

| Viscosity | 100.000 mPa∙s |

| Operational capability | Can be installed on all ecoflow diaphragm metering pumps |

Industries

Pumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Downstream processing

LEWA systems and gradient mixers are used in downstream processing of chemicals and biotechnology. We look forward to receiving your inquiry!

More DetailsWet oxidation of waste water

For wet oxidation and other processes, we recommend our tried-and-tested LEWA diaphragm pumps. Ask our experts for more information!

More DetailsExtraction with supercritical fluids

Processes with supercritical fluids in pharmaceutical, food and beverage industries. Ask our experts for more information!

More DetailsPharmaceuticals production

Metering pumps and metering systems must meet the following demands of pharmaceutical production.

More DetailsProduction of edible oil

LEWA diaphragm metering pumps are used for the production of edible oil. We are happy to assist with your individual production process.

More DetailsPharmaceutical spray drying

LEWA provides accurate and efficient diaphragm metering pumps for pharmaceutical spray drying. Consult us!

More DetailsButter production

In order to sustain consistent quality of spreadable butter, ingredients like rapeseed oil, water, and brine are metered flexibly and fully automatically with ecoflow pumps.

More DetailsHomogenization of milk

With LEWA homogenization systems, producers of dairy products can achieve uniform particle size, moisture, and color, for example, in infant formula, and prevent the milk concentrate within it from creaming.

More DetailsProduction of gelatine

In the production of gelatin and in the fabrication of gelatin products, LEWA pumps and systems are used. We would be happy to give you more information!

More DetailsHigh purity systems

Pumps and high purity systems from LEWA are a tried-and-tested solution in the pharmaceutical & biotechnology industry. We are happy to assist with your individual high purity system.

More DetailsDilution of emulsifiers

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant emulsifier dilution.

More DetailsExtracting omega-3 fatty acids using supercritical CO2

LEWA offers optimum pump solutions for these processes, which perform their tasks safe, permanently reliable and efficiently

More DetailsProduction of creams

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant production of creams.

More DetailsFractionation

LEWA pumps and systems fulllfill necessary international standards and regulations for production in regulated industries (GMP)

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsMetering pumps for sterile applications

LEWA manufactures special aseptic solutions, for the metering of sensitive fluids. Ask our pharma experts for more information!

More DetailsEsterification

With LEWA process diaphragm pumps, as well as the NIKKISO Non-Seal canned motor pumps we offer the optimum solution for esterification.

More DetailsSolutions for flavor and color metering in the confectionery industry

LEWA creates custom-made, complete solutions that are ready to implement in your applications.

More DetailsDownloads

Poster LEWA ecoflow Pumpenkopf M900 (DE)

Poster LEWA ecoflow Pumpenkopf M900 (DE)

121 KB

| pdf |

22.02.2019

Poster LEWA ecoflow Pumpenkopf M500 (DE)

Poster LEWA ecoflow Pumpenkopf M500 (DE)

137 KB

| pdf |

22.02.2019

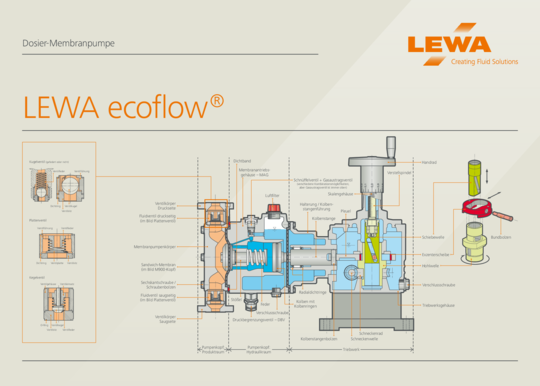

Poster LEWA ecoflow Schnittbild (DE)

Poster LEWA ecoflow Schnittbild (DE)

333 KB

| pdf |

22.02.2019

Poster LEWA ecoflow pump head M500 (EN)

Poster LEWA ecoflow pump head M500 (EN)

439 KB

| pdf |

22.02.2019

Poster LEWA ecoflow Pumpenkopf M200 (DE)

Poster LEWA ecoflow Pumpenkopf M200 (DE)

275 KB

| pdf |

22.02.2019

Poster LEWA ecoflow pump head M900 (EN)

Poster LEWA ecoflow pump head M900 (EN)

121 KB

| pdf |

22.02.2019

Poster LEWA ecoflow pumphead M200 (EN)

Poster LEWA ecoflow pumphead M200 (EN)

627 KB

| pdf |

22.02.2019

LEWA ecoflow maßgeschneiderte Dosierpumpen (DE)

LEWA ecoflow ist ein umfangreiches Baukastensystem für Membran- und Kolbenpumpen. Es kombiniert sieben Triebwerksgrößen mit sechs unterschiedlichen Pumpenköpfen.

3 MB

| pdf |

18.02.2022

LEWA ecoflow bombas dosadoras customizadas (PT)

A ecoflow LEWA é um extensivo sistema modular para bombas dosadoras de diafragma e de pistão.

Ela combina sete tamanhos de unidade com seis diferentes cabeças de bomba.

3 MB

| pdf |

18.02.2022

LEWA ecoflow custom-made metering pumps (EN)

LEWA ecoflow is an extensive modular system for diaphragm and packed plunger metering pumps.

It combines seven drive sizes with six different pump heads.

3 MB

| pdf |

18.02.2022