Solutions polymerization

LEWA pumps offer the following advantages for polyethylene production:

- Hermetically tight

- Pressures over 300 bar

- High flow rates

- Drives with electrical stroke adjustment

- Motors for frequency converter operation

- Wide reproducible adjustment range

- Extremely precise flow rates

- Sturdiness and reliability

- Explosion proof

Areas of application in polymerization

LEWA supplies metering pumps and systems for ethylene polymerization which are used in processes including the following:

- Radical production in high pressure reactors, e.g., autoclave reactors, tube reactors (LDPE)

- Catalytic production in low pressure reactors (MDPE, HDPE, LLDPE)

Application examples are:

- Packaging materials, e.g., shrink wrap, wrapping film, film for “bag-in-box” applications, food packaging film, laminated papers

- Highly stressable containers for industrial use

Background for ethylene polymerization

Process description

Polyethylene consists of hydrogen and carbon. The properties of polyethylene can be changed through copolymerization. It is very resistant to acids, alkaline solutions and other chemicals. Its range of application is limited because it softens at temperatures above 80 °C. Polyethylene is a thermoplastic produced from the polymerization of ethylene. It belongs to the polyolefins and is produced based on ethylene gas.

LDPE (soft polyethylene) results from the high-pressure process and HDPE (hard polyethylene) from the low-pressure process. In both production methods, it appears first as a viscous fluid.

Source: Wikipedia, February 2012

Industries

Pumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsProducts

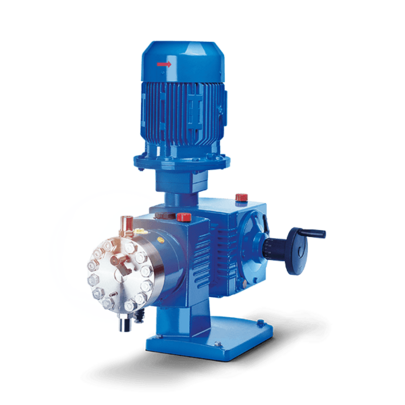

LEWA ecoflow®: The Leading Diaphragm Metering Pump for Precision Fluid Management

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

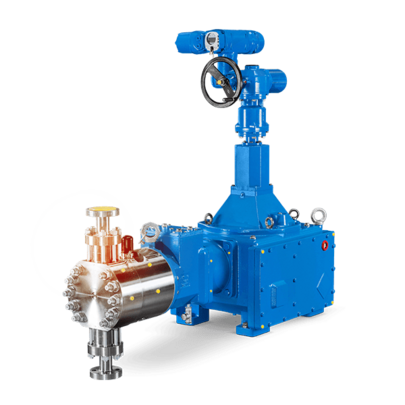

More DetailsLEWA ecoflow®: The Leading Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

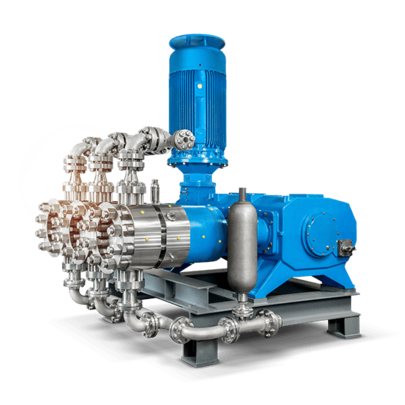

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsLEWA ecofoam® Blowing Agent Metering System

Redundantly designed, absolutely leak-proof system working in combination with extruders for metering various blowing agents in plastic production.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details